Product Overview

Premium Pallet Wrap

By using a premium pallet wrap, you can reduce the plastic you use and your costs while helping save the planet. Have you heard – we’ve introduced New Zealand’s first and only 100% recycled stretch wrap!

More Stretch. Less Plastic. Better Puncture Resistance.

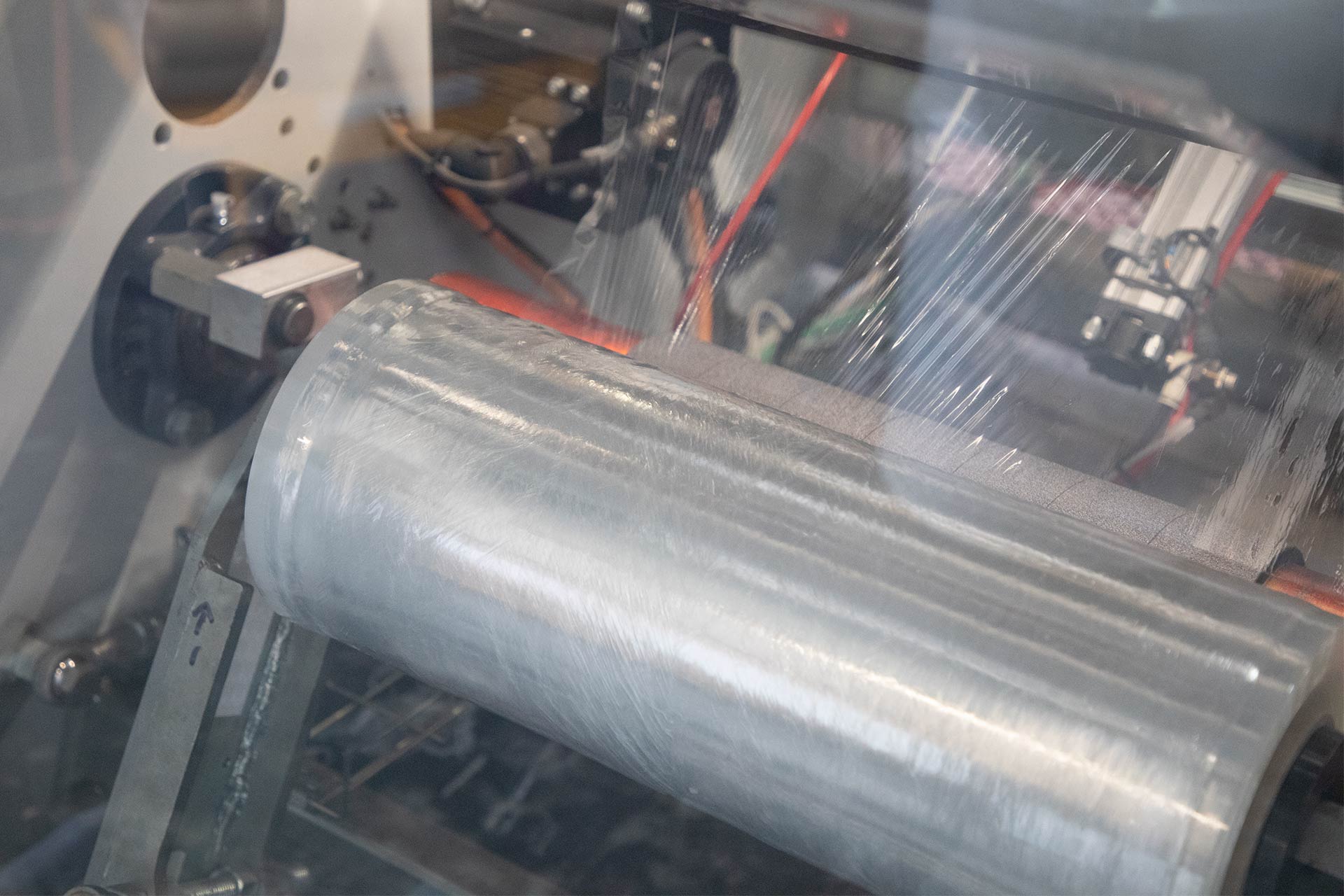

StretchWrap’s market leading cast film is manufactured using leading edge German innovation and technology. It consists of 55 nano layers providing a lighter film with superior strength, puncture resistance and stretch when compared to traditional films. This enables you to achieve better results with less plastic which will reduce your costs and impact on the environment.

Bundle Wrap

StretchWrap Bundle Wraps are manufactured in New Zealand from local and imported materials. This enables us to reuse the cardboard cores and reduce the number of new cores required by up to 80% to support our sustainability objectives. Standard specifications are rolls of 150mm wide x 100m long. These are available in cartons of 10 and 20 rolls. We can also customise your bundle wrap requirements for width and length.

Hand Wrap

Our hand wraps use a cast nanotechnology film, which is made up of 55 nano layers per layer of film, enabling you to use a lighter film to achieve better results with less plastic. This reduces your costs and is better for the environment.

- Smart Stretch Nano 55 Pre-Stretch hand wrap means a tighter load with less plastic

- Power Stretch Nano 55 hand wrap with certified stretch of up to 150% (1 metre to 2.5 metres)

Machine Wrap

Using our wraps and machines could reduce your costs by more than 75%. Ultra Stretch Nano 55 is a high stretch premium machine wrap combining high containment force and puncture resistance to give you peace of mind that your load is safe and secure. For machine wrapping, combining a high stretch film with a pallet wrapping machine that has been optimised for the wrap can greatly increase the stretch achieved, reducing the plastic used to wrap a pallet and thus your costs.

Use Less Plastic

Reduce Costs

Customised Wraps

Every now and then you need something unique and tailored specifically to your products. With our own manufacturing facilities in New Zealand, we can customise your wraps to make sure they are fit for purpose and you limit any unnecessary waste.

- For Bundle, Hand and Machine Wraps, we can customise widths and lengths

- For Pre-Stretch, we can customise length and thickness (microns)

StretchWrap Manufactures Pre-Stretch in New Zealand

What’s the difference?

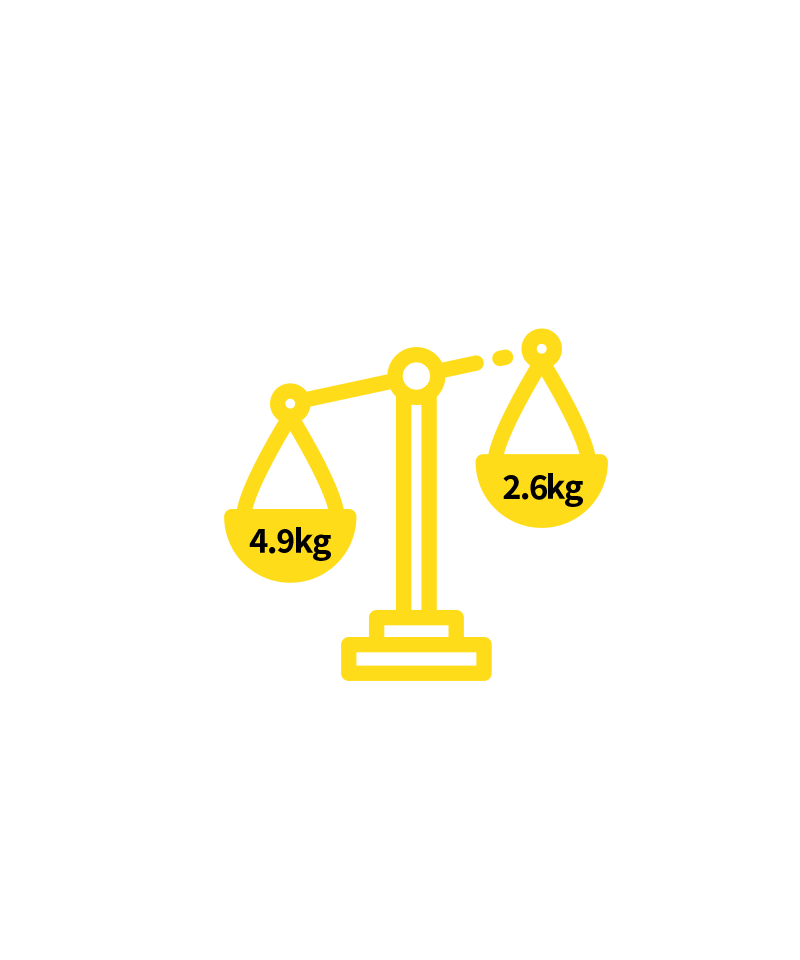

- 47% reduction in plastic used

- Double strength edges

- Pre-stretched to maximise utility and minimise plastic waste, while retaining superior load protection

- Standard 800 metre rolls

- Custom lengths available

Our 55 layer nano film is manufactured using technology from Windmöller & Hölscher in Germany, producing lighter films with higher strength, stretch and puncture resistance.

Simply put, our films deliver cost effective superior performance you can trust, even in the most demanding applications.

Manufacturing Industry

Warehousing & Distribution Industry

Wholesale, Retail & Packing Industry

Food & Beverage Industry

Logistic & Transport Industry

Pallet Wrap Machines to Rent, Buy or Borrow

- Access to Free Standby Pallet Wrap Machine – Customers have access to a standby pallet wrapping machine in the event of a peak demand event or failure of one of their machines.

- Rent – if your prefer opex over capex, you can rent a pallet wrap machine and secure preferential pricing on consumables.

- Buy – if your prefer to own your machine, we can supply you with the pallet wrap machine that best meets your needs and secure preferential pricing on consumables.

Less Cost

With our Nano 55 pallet wrap, every roll goes further. Its superior stretch means you use as much as 40% less plastic compared with the industry standard. Less plastic means lower costs, it’s better for the environment and less labour cost due to fewer roll changes. StretchWrap will deliver you a net cost saving when you switch to our Nano 55 pallet wraps. Contact us for a demonstration on how we can deliver less cost to you.

Add up your pallet wrap usage over a year. Then factor in fewer orders and reduced storage space afforded by our pallet wrap and you’re looking at savings thousands of dollars for a typical warehouse in New Zealand.

Better Protection

Myth Buster: a higher micron pallet wrap no longer means superior strength. Advances in nanotechnology mean we’re able to produce layered pallet film using a raw material that outperforms standard pallet wrap products in every way. Just as plywood is to wooden boards, multi-layered stretch film offers less weight and more strength.

From glassware to fresh produce, when your products absolutely must be safeguarded during transport, you rely on the pallet wrap film to securely restrain your load. Pallet wrap does not get any better than our 55 Layer Nanotechnology Film, available exclusively in New Zealand from StretchWrap.

Environmentally Responsible

Just because it’s “recyclable” doesn’t mean it actually gets recycled!

We don’t subscribe to virtue signalling like “recyclable” so we support our customers in recycling their plastic to guarantee that it is in fact recycled so they can demonstrate their GREEN credentials. Starting with our Auckland customers, we will work with you to collect and recycle your clear, clean LLDPE and LDPE plastic.

Furthermore, as StretchWrap manufactures products in New Zealand, we work with our customers to take back the cardboard cores used in the pallet wrap and reuse them. Cores are typically reused up to 5 times before being recycled which means an 80% reduction in the number of new cores used.