Case Study: CaroTrans CFS

How CaroTrans saved 40% on labour costs when unloading containers

A container freight specialist based in Auckland, CaroTrans, spend much of their labour costs on unloading containers and wrapping pallets as they package goods ready for the next phase of their journey.

The CaroTrans Operation

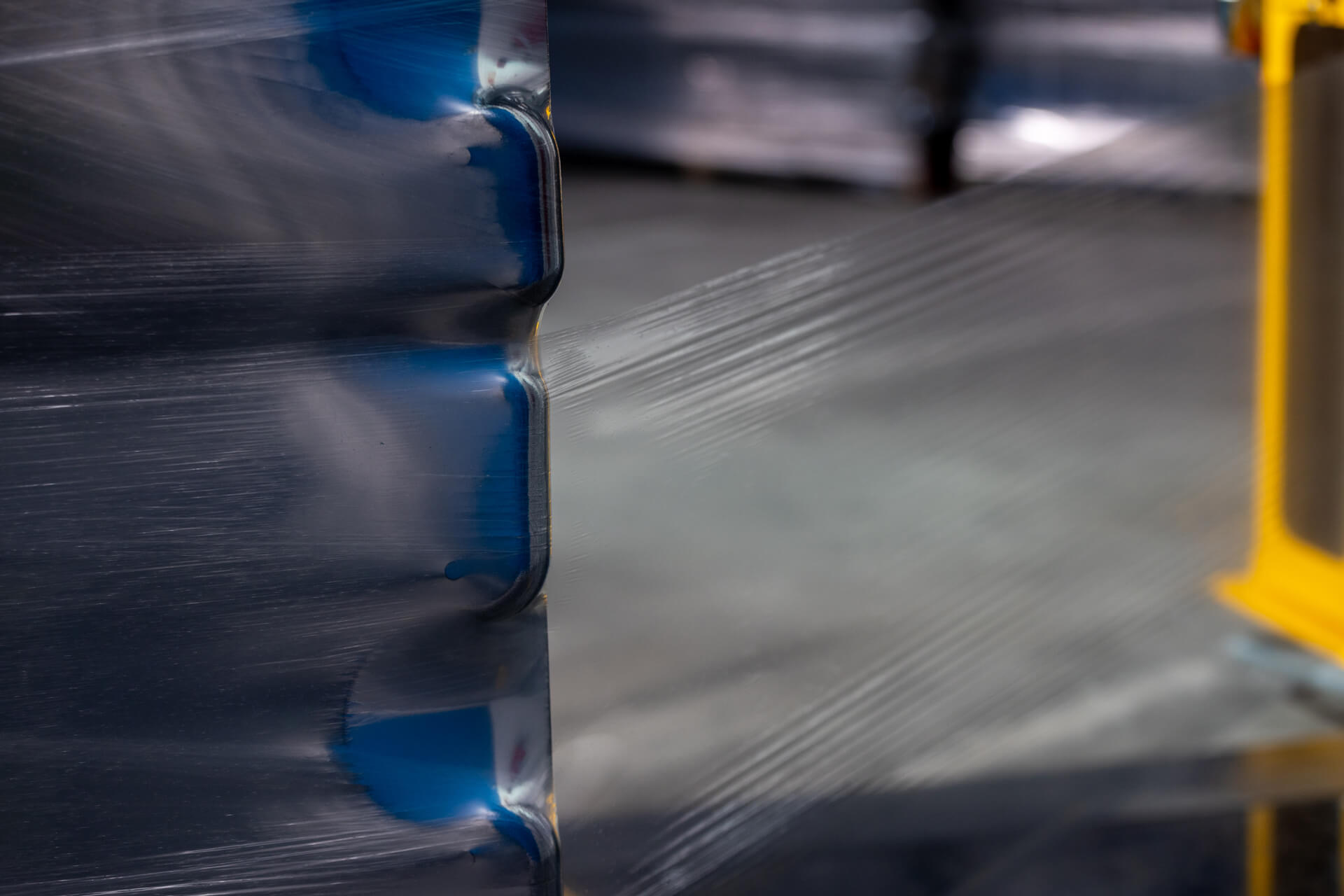

CaroTrans traditionally wrap pallets by hand but a recent shipment of large black plastic floatation containers for a customer in aquaculture meant the pallets were bulky and tall, at around 2.5 metres tall. This made it difficult to wrap and labour intensive.

In a simple change to their warehouse packaging operations, CaroTrans rented a pallet wrap machine from StretchWrap and immediately reduced their labour costs in this area by up to 40%. The pallet wrap machine could wrap the full height of the pallets, removing the difficulty of hand wrapping tall loads and the health and safety risks that come with it. Renting the pallet wrap machine reduced the time usually taken to process, unload and package the cargo by nearly 60%, facilitating a significant boost to their productivity and reduction in costs.

The Challenge

Wrapping extra height pallets is a challenge, especially when using hand wrap. For CaroTrans, this shipment involved pallets at nearly 2.5 metres in height which means they are too high to effectively wrap by hand and it is very difficult to secure the top layer tightly.

The Solution

StretchWrap supplied CaroTrans with a pallet wrapping machine on a short term rental, and paired with the correct pallet wrapping film for their operations.

The pallet wrap machine allows the product to sit firmly upright on the pallet, and at 2.8m high, the machine could securely wrap the 2.5m high pallets in a matter of minutes.

Prior to using StretchWrap’s pallet wrapping machine, CaroTrans had a team of up to five people unloading the containers. “With the wrapping machine, we found that we only needed a team of three,” says Neil Harding, Warehouse Operations at CaroTrans. This translates to up to a 40% saving in labour costs. In dollar terms, the amount is significant when you tally up the savings over a month, quarter or a year.

“Besides reducing our labour costs, we used less stretch wrap and also unpacked the containers in a shorter time than before,” continues Neil.

A key feature of our pallet wrapping machines is the infrared laser, which means that you can wrap black cargo. With standard machines, the laser can’t determine the height of the black cargo so it is unable to be operated automatically. This impacts productivity and consistency and increases costs.

The extra height of the machine over traditional machines means that you can wrap taller pallets and double stacked pallets, too.

On the new machine pallet wrap provided by StretchWrap, Neil adds, “It does the job and seems to have the right amount of adhesive to firm the pallets nicely. We absolutely use less wrap than before.”

With the ability to rent a pallet wrap machine as required, CaroTrans can now maximise their efficiency and productivity for each shipment. Neil unreservedly recommends StretchWrap to any warehouse seeking to optimise their pallet wrapping operations.

Besides reducing our labour costs, we used less stretch wrap and also unpacked the containers in a shorter time than before.

Neil Harding, Warehouse Operations – CaroTrans CFS

The infrared laser allows you to machine-wrap black cargo.